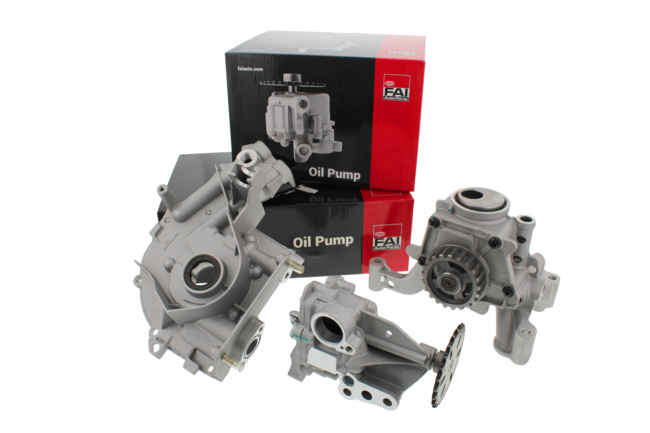

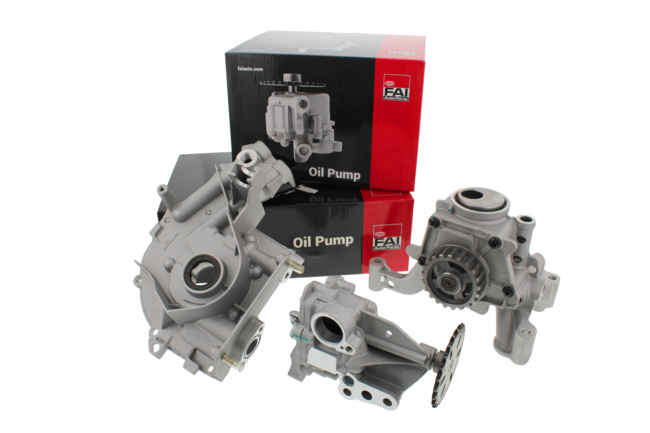

Oil Pumps

FAI’s extensive range of oil pumps encompasses all common pump designs and drive types. The guide below is a brief explanation of the pumps seen throughout this catalogue, which is

often the differentiating piece of application data.

Drive Types:

- Crankshaft Driven – Situated directly on the end of the Crankshaft, this design usually incorporates a cover which sits directly above the Sump.

- Chain Driven – With more modern vehicles being equipped with Timing Chains, the Oil Pump has followed this trend by being driven by a Chain system.

- Belt Driven – Equipped with a Pulley rather than a Sprocket, this design is driven by a Rubber Belt, much like a Water or Vacuum Pump.

- Intermediary Shaft Driven – Driven by an auxiliary source such as a Lanchester Unit or Balance Shaft, this is a compact design most commonly used in VW/Audi/Seat/Skoda

- Gear Driven Pump – Gear driven pumps include an intermeshing gear which are predominantly used on Heavy Duty Diesel applications.

- Shaft Driven Pump – Incorporating a drive shaft, this type of pump is usually driven off a Camshaft or Intermediary Shaft. These usually have a Spline or Slot fitment on the end of the shaft.

Our full range comprises of:

- Gear Pumps – Also known as Twin Gear pump, this design houses two gears running in opposite rotation to one another. This design is used in Chain Driven/Gear driven pumps most frequently.

- Vane Pumps – Vane pumps are being used more widely in modern applications due to their capacity for Variable Flow control. Unlike other pumps, it can regulate the flow rate of Oil thanks to its sliding Vane design.

- Crescent Pumps/Rotor Pumps – Generally used in most Crankshaft Driven pumps, this design comprises of 1 large outer gear, and 1 small inner gear sitting off-centre to one another. The Crescent shaped void left between the two gears is where the flow control and vacuum is produced.