There’s gold in them hills.

If someone mentions sump pans as a profitable product you wouldn't think they were serious, "It's under the car, what could go wrong?". What could go wrong indeed, certainly in the UK we have seen an increase in traffic calming measures, speed bumps to you and me, as well as a serious deterioration in the road surface. Corrosion from poor paint finishes or exterior damage, salt & water ingress or a failed seal can all contribute to the sump pan failing and potentially causing serious engine failure. This would suggest that the bottom of the engine is potentially the worst place to be.

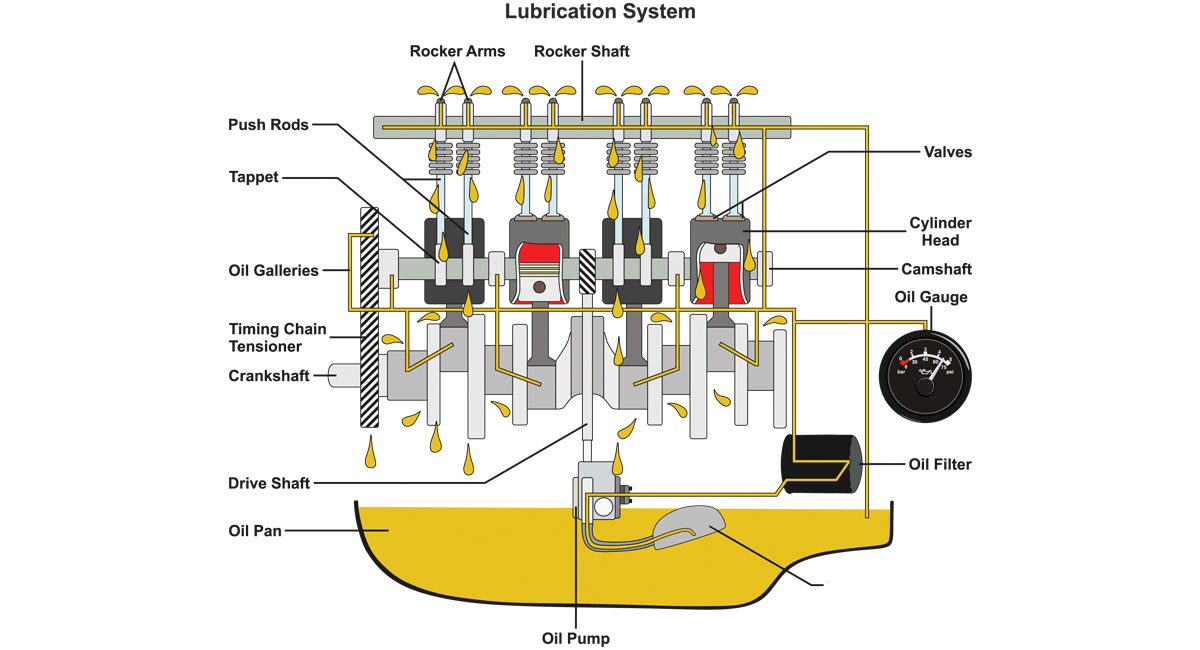

All sumps available from FAI are 'wet sumps', serving as a reservoir for the engine oil required in the lubrication of the bearings, pistons, valve train and other internal components. The wet sump is a more practical design as it is bolted to the bottom of the engine so there is no need for external hoses or pipes. Wet sump engines will have a single oil pump fitted, generally in close proximity to the sump so the oil pick up pipe can feed from the sump.

When the engine is off, the majority of oil will find its way back to the sump via gravity, leaving a coating of oil on most components. On startup the crankshaft will drive the oil pump via chain, belt or gear drive to suction the oil into the oil lines through the filter and into the moving parts of the engine. The oil will cycle round and find its way back to the sump for the cycle to begin again.

FAI Sump pans are available in steel or aluminum dependent on the vehicle manufacturers requirements and each contain a drain plug for ease of oil changes.

The initial range of FAI sumps consists of 50 separate references all of which are leak and pressure tested. You and your customers can rest assured of the quality signified by the laser etched FAI logo on every pan. All our sump pans include the sump plug and gasket or silicon as required.